- Industries

- /

- Marine

Marine industry

Superalloys Engineering is an innovative company with “top of the line” solutions in marine industry. The company operates a fully equipped mechanical workshop, specialized in the manufacturing of high quality industrial spare parts and machine element components for internal combustion engines. Babbit plain thin wall bearings & bushes – standard, oversized or undersized -coated and overlayed with white metal, aluminum and copper based alloys constitute trimetallic (with Cu based interlayer) or bimetallic structures providing ultimate low friction coefficient performance during engine operation.

Thermal Barrier Coatings (TBCs) for internal combustion engine valves, cylinder heads and mechanical seals with plasma spray ceramics (Zr02-Y203, Cr203, SiOu, Al203-Ti02).

Application Area

- Heavy Duty Diesel Engines

- Marine Engines

- Electrical Generators

- Turbines - Pumps

- Compressors

- Heavy Trucks

- Earthmoving Machinery

Components

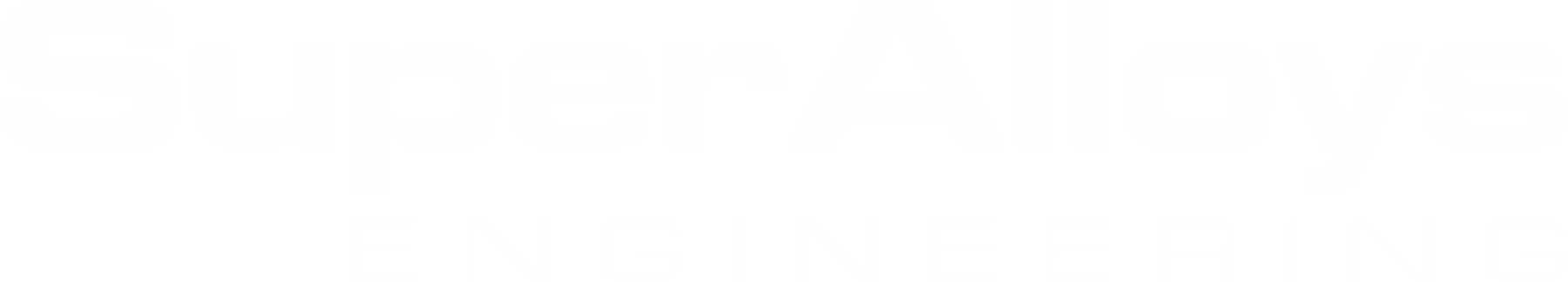

- Plain Bearings (Crankpin & Main Joumal)

- Bushes

- Thrust Bearings

- Engine Valves with Ceramic coating

- Engine Cylinders & Heads

- Crankshafts & Camshafts

- Mechanical seals

- Earthmoving Clutches

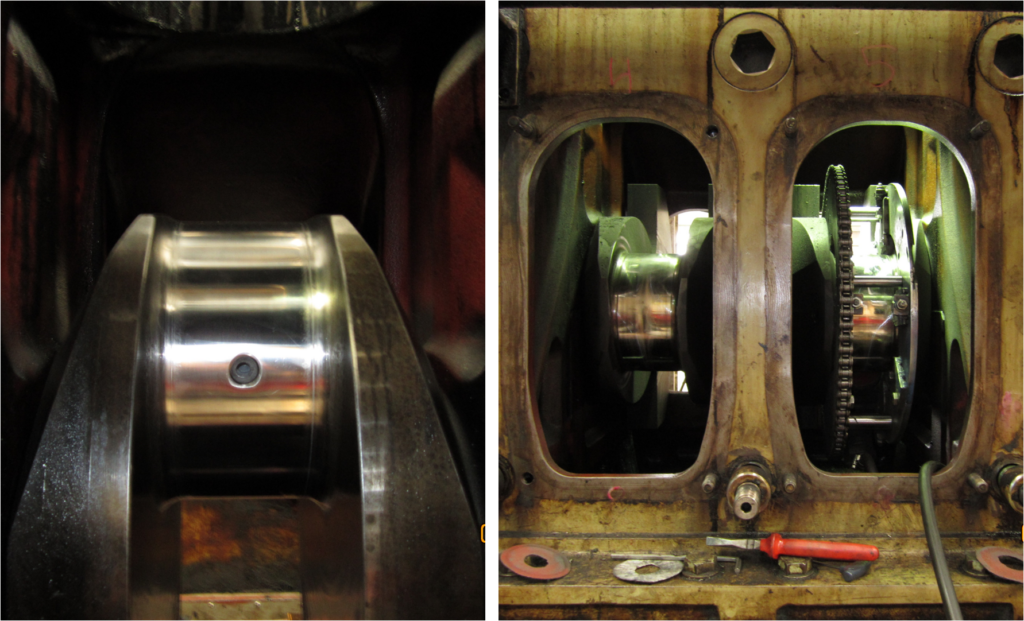

Since 2003 the activity was also focused on urgent maintenance services with out patented in-situ portable machine tools, in order to provide precision machining on crank pins and main journals of crankshafts.

SuperAlloys Engineering provides full service support, in-situ repair including the customized spare parts manufacturing under any conditions urgent or not, anytime and all aroung the globe.